As a kind of high-precision and multi-functional digital printing equipment, UV printer has been widely used in advertising, packaging, crafts and other fields in recent years. Among them, visual positioning function and metal color printing are the two major technical highlights of UV printers. This article will analyze the advantages of visual positioning in detail, and delve into the technical limitations and solutions of UV printers when printing metallic colors.

1. Advantages of visual positioning function of UV printer

Visual positioning function is an advanced technology in UV printers, through the camera and image recognition system, to achieve accurate positioning of the print position. Here are the specific advantages:

(1) High-precision positioning

Function Description: The visual positioning system captures the position and shape of the printed object through the camera, and automatically adjusts the position of the print head to ensure accurate alignment of the pattern.

Advantages: Suitable for irregular objects or printing tasks that require accurate alignment, such as mobile phone cases, crafts, packaging boxes, acrylic signs, etc.

(2) Automated operation

Function Description: The visual positioning system can automatically identify the position and Angle of the object without manual adjustment.

Advantages: Reduce manual operation, improve production efficiency, reduce error rate.

(3) Multi-object batch printing

Function description: The visual positioning system can identify the position of multiple objects at the same time to achieve batch printing.

Advantages: Suitable for large-scale production, improve production efficiency.

(4) Complex pattern counterpoint

Function Description: The visual positioning system can identify the edges and details of complex patterns to ensure accurate alignment of patterns.

Advantages: Suitable for printing tasks requiring high precision, such as artwork reproduction, precision parts marking, etc.

(5) Save materials

Function description: Through accurate positioning, reduce printing errors and avoid material waste.

Advantages: Reduce production costs and improve resource utilization.

2. The reason why UV printer can not print metal color directly

Although UV printers are very good at color performance, there are certain technical limitations when printing metal colors directly. Here are the main reasons:

(1) Ink composition limitation

The reason: Ordinary UV inks are mainly composed of pigments and resins, and cannot simulate the luster and reflection effects of metals.

Impact: The printed color lacks a metallic texture and cannot achieve a true metallic effect.

(2) Technical limitations of sprinkler heads

Reason: The nozzle design of ordinary UV printers is not suitable for spraying ink containing metal particles. The amount of ink jet of a spray hole in the current market nozzle is generally 5-10pl, which is thinner than a hair. If you print metal particles, it will inevitably block the nozzle. If you want to print metal color, then the minimum amount of ink jet of a nozzle hole is 30-40pl, and about 100pl is the best effect. However, if the metal color is printed directly, the fabric print quality is not delicate enough, and the noise will be very obvious.

Impact: Metal particles are easy to block the nozzle, affecting the print quality and equipment life.

(3) Adhesion problem

Reason: The adhesion of metallic ink on ordinary materials is poor, and it is easy to fall off.

Impact: The durability of the printed pattern cannot be guaranteed.

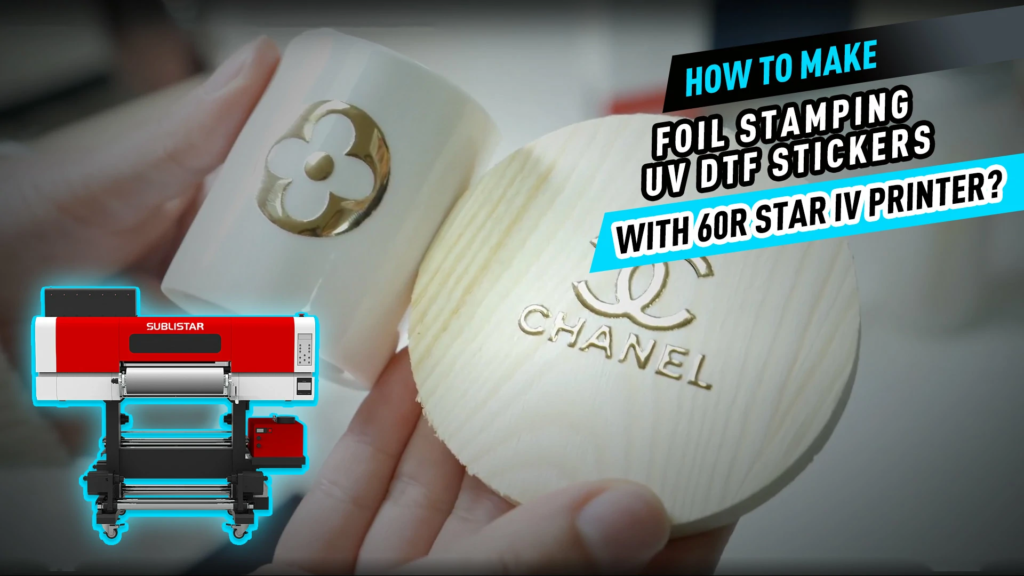

3. Steps to achieve metallic color printing without replacing the nozzle

If you want to achieve metal color printing without replacing the nozzle, you can achieve it by covering the metal film. Here are the steps:

(1) Preparation

Material: Metal film (such as hot stamping film, hot silver film, Sublistar also provides multi-color hot stamping film, such as green hot stamping film, blue hot stamping film, etc.) UV printer, substrate, waste film.

Equipment: Laminating machine or manual film pressing tool.

(2) Print the base map

Steps:

A. Use the UV DTF printer to print the base map on the surface of the A film, the base map can be a pattern or text.

B. Ensure that the color and design of the base image can be contrasted with the metal film to enhance the visual effect.

(3) Waste membrane

Steps:

A. Cover A layer of waste removal film on the surface of the printed A film bottom map.

B. Ensure that the waste film covers all the areas that need to be covered with metal film, and there is a layer of glue on the waste film, which will stay in the position where the gold film needs to be covered.

(4) Metal film

Steps:

A. Cover the metal film evenly on the surface where the waste film has just been torn off.

B. Use A laminating machine or manual film pressing tool to firmly press the metal film on the surface of the A film object.

(5) Remove excess metal film

Steps:

A. Wait for the metal film to firmly combine with the film of the printed pattern, and gently tear off the excess metal film.

B. Ensure that only the metal film of the pattern part remains on the surface of the object.

(6) Curing treatment

Steps:

A. Use UV lamp or hot press to cure the coated part to enhance the adhesion of the metal film.

B. Ensure that the metal film is firmly attached and not easy to fall off.

(7) Post-processing

Steps:

A. Check the effect of the film, if necessary, local repair.

B. Clean the surface of the object to remove residue.

4. Advantages and precautions of metal film

(1) Advantages:

Strong metallic texture: metal coating can achieve true metallic luster and reflection effect.

Wide range of application: suitable for a variety of materials and objects, such as plastic, glass, wood, metal and acrylic.

Lower cost: The cost of metal coating is lower than replacing the nozzle or using special ink.

(2) Precautions:

Glue selection: Select a special glue suitable for metal film and printing material to ensure adhesion.

Operating environment: Keep the operating environment clean to avoid dust affecting the coating effect.

Equipment maintenance: Clean and maintain the hot press or film pressing tool regularly to ensure the normal operation of the equipment.

Step 5 Summarize

The visual positioning function of UV printers significantly improves printing efficiency and quality through high-precision positioning and automated operation, which is especially suitable for printing tasks with complex patterns and irregular objects. However, due to the limitations of ink composition and sprinkler technology, UV printers cannot directly print metallic colors. By covering the metal film, metal color printing can be achieved without changing the nozzle, providing more possibilities for personalized customization and high-precision printing. With the continuous development of technology, UV printers will show their value in more areas and promote innovation and progress in the digital printing industry.