Understanding the Core Components of Laser Marking Systems

The Science Behind Laser Technology

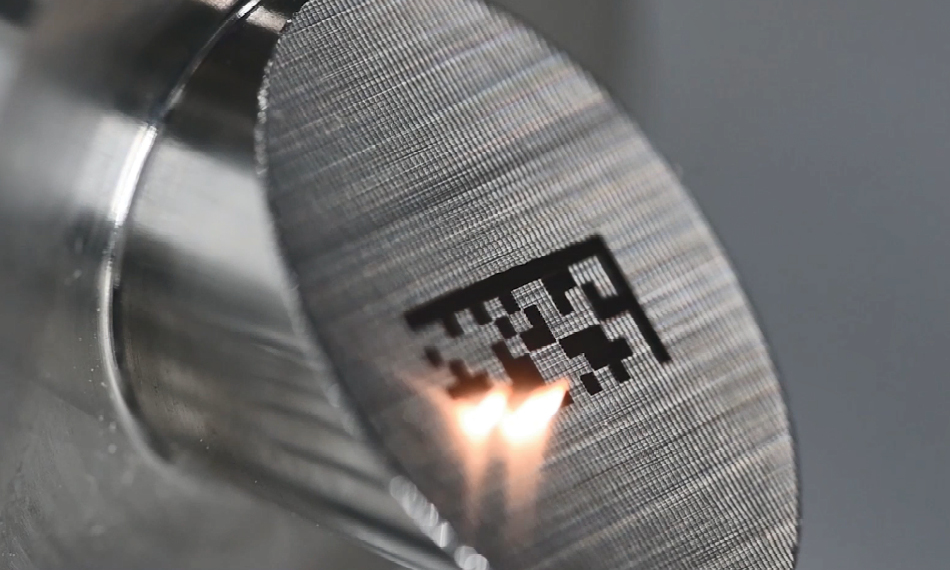

Laser marking technology employs focused beams of light to create precise markings on various surfaces. The core principle hinges on stimulated emission, where energy is transferred to photons, producing a coherent light beam. This beam is highly concentrated, allowing for detailed markings that can resist wear and tearing over time. Understanding the wavelength is crucial, as it determines how well the laser interacts with different materials. For example, CO2 lasers, with their longer wavelengths, are excellent for organic materials like wood or leather, facilitating deep engravings and marking. On the other hand, fiber lasers emit shorter wavelengths, making them suitable for metals and plastics where precision is paramount. This fundamental understanding of how laser light interacts with materials is critical for achieving the desired results in marking and engraving applications. Advancements in laser technology have enabled greater versatility, allowing for markings on a range of substrates from industrial components to intricate jewelry designs. Understanding the different laser technologies, such as continuous-wave and pulsed lasers, helps users select the appropriate system for their specific requirements. Continuous-wave lasers produce a steady beam ideal for cutting, while pulsed lasers deliver short bursts of energy suitable for engraving, where precision is necessary.

Types of Lasers and Their Unique Applications

Different types of lasers offer distinct advantages, depending on the materials being processed. CO2 lasers, for instance, excel in marking non-metallic materials like rubber, glass, and plastic. They are frequent choices in packaging industries for creating barcodes or expiration dates on products, as well as in the woodworking sector for intricate designs. Fiber lasers, on the other hand, are renowned for their efficiency and durability, making them suitable for metal marking applications. Their ability to create high-contrast markings on surfaces is particularly beneficial in industries such as automotive, electronics, and aerospace, where identification and traceability are vital. The most notable application for fiber lasers is dot peen marking, which provides a permanent and tamper-proof marking solution. YAG lasers, though not as common due to lower efficiency, still have specific applications, particularly in the medical field for laser surgery and tattoo removal. Similarly, UV lasers, known for their short wavelengths, provide superior precision, making them ideal for marking delicate materials such as glass and certain plastics without causing thermal damage. Selecting the right type of laser is crucial not just for efficiency but for achieving the desired aesthetic outcomes in the marking process.

Choosing the Right Laser Printer for Your Needs

Selecting a laser printer for marking applications involves multiple considerations, including the type of materials you will be marking, the speed of production, and the complexity of the designs. High-quality laser printers offer features like adjustable power outputs and a variety of focus depths, ensuring adaptability across different projects. One important factor to consider is the printer’s compatibility with various software solutions. A laser printer that integrates seamlessly with design software allows for greater creativity in crafting unique markings. Additionally, factors such as operating costs, both in terms of initial investment and ongoing maintenance, should be assessed. Some laser systems come with extended warranties and support, which can significantly bring down the total cost of ownership over time. The size and power of the laser machine are also pivotal; larger machines can handle bigger jobs at a quicker pace, but smaller machines can be more versatile and easier to fit into compact workspaces. Particularly for small businesses or startups, investing in a system that can grow with their business needs is vital. It’s essential to conduct thorough research and potentially seek expert guidance to ensure that the chosen laser printer aligns with your operational goals and product offerings.

Must-Have Accessories to Enhance Your Laser Marking Experience

Substrates: The Foundation of Quality Marking

The substrate—the material onto which the laser marking will be applied—plays a crucial role in the overall quality of the mark. Each substrate has its own characteristics, and understanding these can mean the difference between a clean, crisp marking and one that is faded or illegible. Common substrates include metals, plastics, leather, glass, and paper, each requiring specific laser settings and marking techniques. Metals, which typically demand high-energy lasers, benefit significantly from proper preparation. For example, materials such as aluminum and stainless steel require specific treatments like anodizing or passivation to optimize marking quality. Engraving on plastic, in contrast, calls for precise modulation of laser focus to avoid damaging the surface. The use of test samples can facilitate a better understanding of how to adjust laser settings for various substrates and prevent costly mistakes in production. In addition to the material properties, the surface texture also impacts marking quality. Smooth surfaces usually yield sharper marks compared to rougher finishes. Therefore, choosing the proper substrate is paramount; not only does it affect the visual appeal of the marked product, but it also contributes fundamentally to its longevity and resistance to weathering, chemicals, or abrasion.

Focusing Lenses: The Key to Precision

Focusing lenses are among the most vital accessories for achieving precision in laser marking applications. These lenses are critical for directing the laser beam to the desired focal point, thus optimizing the energy density and depth of the marks produced. The choice of lens can vary based on the application, as different jobs may require different focal lengths and diameters. Standard setups typically utilize 2” and 4” focal length lenses; however, certain intricate designs might call for specialized lenses that accommodate more complex angles or smaller focal spots. Understanding the degree of focus—how narrowly the lens can concentrate the beam—can greatly influence both marking sharpness and engraving depth. Moreover, lens quality directly affects the efficiency of laser operations. High-quality lenses minimize losses from unwanted reflections, ensuring that the maximum amount of laser energy is focused into the workpiece. Maintenance of these lenses, including routine cleaning and proper handling, is essential for sustaining their performance and ensuring longevity.

Cooling Systems: Keeping Your Operation Smooth and Efficient

The need for an efficient cooling system in laser marking technology cannot be overstated, particularly when operating high-power lasers that generate significant heat. Heat can adversely affect performance and lead to premature failures. Effective cooling solutions, including air-cooled and water-cooled systems, help maintain optimal operational temperatures, ensuring that the laser marking system runs smoothly and reliably. Air cooling systems, while simpler and cheaper, may not suffice for higher-powered models, where water cooling becomes necessary to adequately dissipate heat. High-performance water chiller units provide the precise control needed for temperature variations, thus preserving both the integrity of the laser and the quality of the marks produced. Regular maintenance of cooling systems is crucial to avoid downtime and operational inefficiencies. This includes routine checks for coolant levels and temperatures, as well as cleaning lines and filters to ensure unobstructed flow. Investing in robust, reliable cooling solutions not only enhances the lifespan of laser equipment but positively impacts production efficiency and product quality.

Safety First: Essential Protective Gear for Operators

Understanding Laser Safety Guidelines

Laser marking operations, while efficient and effective, do pose potential safety risks. Understanding the laser safety guidelines is essential for protecting both operators and the surrounding environment. Various governing bodies, including the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA), provide comprehensive regulations encompassing laser safety training, operational protocols, and proper equipment usage. One of the main dangers inherent in laser marking is exposure to the beam, which can result in eye injuries or skin burns. Thus, all operators should undergo thorough training that includes identification of the risks associated with their specific laser systems, recognizing caution zones, and employing appropriate emergency procedures. Regular safety audits can help reinforce these practices and ensure compliance with established guidelines. Moreover, proper signage and protective barriers around laser marking workspaces are equally important. They serve as visual reminders and physical deterrents against unintended exposure to the laser beam. Implementing a culture of safety in the workplace also ensures that employees are not only aware of the risks but also focused on proactive measures to mitigate them.

Protective Eyewear: A Non-Negotiable Investment

Protective eyewear is a fundamental necessity in any laser marking operation. Operators should select laser safety glasses that provide adequate protection for the specific wavelength of the laser being used. Since lasers emit varying wavelengths, eyewear designed for shorter wavelengths (like those used in fiber and UV lasers) typically differs from that suited for CO2 lasers. It’s imperative to ensure that these glasses are not just effective but also comfortable, allowing operators to wear them for extended durations without compromising visibility or comfort. Often, safety glasses with anti-fog coatings and lightweight designs are preferable, as they improve usability in busy workshops. Regular checks for wear and damage should also be part of standard operating procedures. Scratches or any signs of degradation can significantly reduce the effectiveness of the protective eyewear, increasing the risk factors for the wearer. Upholding the highest safety standards, such as replacing damaged glasses immediately and routinely educating employees on the importance of eye protection, cultivates a safer work environment.

Ventilation Systems: Guarding Against Harmful Fumes

Ventilation systems play a critical role in maintaining air quality during laser marking processes, especially when working with materials that may release toxic fumes or smoke. Laser marking certain substrates, such as plastics and composites, can generate hazardous gases that pose health risks to operators. Implementing proper ventilation is necessary to remove these fumes and ensure a safe working environment. A localized exhaust system, tailored specifically for laser workstations, can efficiently capture harmful emissions right at the source. Such systems often include filters that capture particulates and neutralize dangerous fumes before they are released into the environment. These systems should be regularly maintained to ensure efficiency and compliance with relevant health regulations. In addition to localized systems, general air circulation is essential as well. Drawing fresh air into the workspace helps dilute any residual contaminants, while regular monitoring of air quality is necessary to safeguard operator health. Creating a comprehensive strategy that encompasses both localized and general ventilation systems not only protects employees but can also improve overall workplace productivity.

Innovations and Future Trends in Laser Marking Accessories

The Rise of Smart Laser Marking Accessories

The evolution of smart technologies is dramatically transforming laser marking operations. The integration of IoT (Internet of Things) into marking systems is creating opportunities for real-time monitoring, predictive maintenance, and remote control capabilities. These advancements provide operators with the tools to streamline workflows by enabling data collection that can be analyzed for process optimization. One of the emerging trends is the use of sensors that deliver immediate feedback on operational parameters. For example, advanced sensors—often part of modern laser marking accessories can monitor temperature and humidity levels, alerting operators to fluctuations that could impact marking quality. Additionally, systems enhanced with AI algorithms can interpret this data and recommend real-time adjustments, significantly reducing manual intervention and potential errors. As workplaces become more automated, smart laser marking accessories are playing a vital role in supporting Industry 4.0 initiatives, where interconnected devices collaborate seamlessly. This not only improves operational efficiency but also strengthens traceability, supporting compliance with rigorous industry standards.

Sustainable Practices: Eco-Friendly Materials in Laser Marking

As the global emphasis on sustainability grows, so does innovation in eco-friendly materials used in laser marking operations. Businesses are increasingly shifting towards biodegradable substrates and inks that minimize environmental impact. These materials not only offer a sustainable alternative but can also enhance brand image as consumers become more environmentally conscious. Moreover, advancements in laser technology are enabling more efficient material usage, where laser systems are designed to minimize waste. For instance, intelligent cutting algorithms can reduce off-cuts during the marking process while maintaining high-quality results, thus improving resource utilization. Investing in sustainable practices is not only an ethical consideration but often translates into cost savings over time. Companies adopting these methods can also benefit from governmental incentives and subsidies aimed at encouraging positive environmental practices, demonstrating that sustainability can align with business interests.

Integrating AI to Optimize Marking Processes

Integrating AI systems into laser marking processes is setting a new standard for operational efficiency. AI can be leveraged in various stages, from design formulation to execution optimization, to ensure that marking processes are not just fast but also maintain high quality and accuracy. AI-driven software can analyze complex data patterns and user interactions, thereby enabling operators to create dynamic marking solutions tailored to specific projects in real-time. Moreover, predictive analytics can forecast maintenance needs, alerting users to potential issues before they disrupt operations—thus mitigating downtime and associated costs. Furthermore, AI can significantly enhance the quality control processes. By using machine learning algorithms, systems can examine finished marks for consistency in quality, even identifying anomalies that human inspectors might overlook, thus ensuring that each product meets stringent quality standards. The incorporation of AI technology in laser marking paves the way for significantly optimized processes, offering a competitive edge in today’s fast-paced market. In conclusion, understanding the essential components and accessories for laser marking systems is critical for achieving precision and efficiency. From selecting the right equipment to optimizing operational safety and efficiency, these elements chart a comprehensive path toward elevated quality and reduced operational costs in laser marking applications. As technology continues to evolve, keeping abreast of innovations—especially those focused on sustainability and smart integration—will be key to staying competitive in this dynamic industry.