HMIs screens and displays are critical tools for controlling and monitoring industrial systems efficiently. Human-machine interface (HMI) technology allows operators to interact intuitively with machinery, making processes more efficient and easy to control. Whether you’re implementing HMI in manufacturing, energy, healthcare, or transportation, understanding the full capabilities of HMI screens and displays can transform your operations.

In this comprehensive guide, I’ll walk you through the different types of HMI screens, their benefits, essential features, and how to choose the best options for your needs. Let’s dive in.

Table of Contents

What Are HMIs Screens and Displays?

Human-Machine Interface (HMI) screens and displays are visual platforms that allow operators to control, monitor, and diagnose the performance of machinery and industrial processes. They function as a bridge between the operator and the machine, providing real-time data visualization, operational insights, and interaction capabilities. HMI screens can range from simple graphical displays to sophisticated touch screens with advanced functionalities.

Why Are HMIs Screens and Displays Important?

HMIs screens and displays enhance control and visibility over complex systems, enabling more informed decision-making and quicker response times in industrial settings. They allow operators to monitor real-time metrics like temperature, pressure, flow, and equipment status. This functionality makes HMI a crucial element in sectors that rely on precision and operational efficiency.

Types of HMIs Screens and Displays

- Basic Text-Based Displays

Text-based displays are simple interfaces that primarily show alphanumeric data, such as status alerts and numerical outputs. They’re ideal for smaller, less complex systems where detailed visualization isn’t essential.

- Graphical HMI Displays

Graphical displays represent data visually through images, icons, and basic graphics, which make it easier for operators to interpret data quickly. Common in manufacturing, they provide a clear overview of machinery status and system operations.

- Touchscreen HMIs

Touchscreen HMIs combine functionality with ease of use, allowing operators to interact directly with the display. These screens offer fast navigation and are highly customizable, with multi-level displays and intuitive controls.

- Web-Based and Mobile HMI Solutions

These HMI types allow operators to access systems remotely via web browsers or mobile devices. Ideal for distributed systems, they provide flexibility, letting operators monitor systems outside the immediate location.

- Industrial PC-Based HMIs

PC-based HMIs offer high levels of customization, graphical quality, and processing power. They are best suited for complex systems requiring detailed data analysis and control.

Key Features of HMIs Screens and Displays

- User-Friendly Interface

HMIs should offer an intuitive design, enabling operators to navigate without difficulty. Look for clean layouts and customizable dashboards. - Responsive Touch Control

Fast, reliable touch response improves usability, particularly in high-paced environments. Capacitive touchscreens generally offer better responsiveness and durability. - High-Resolution Display

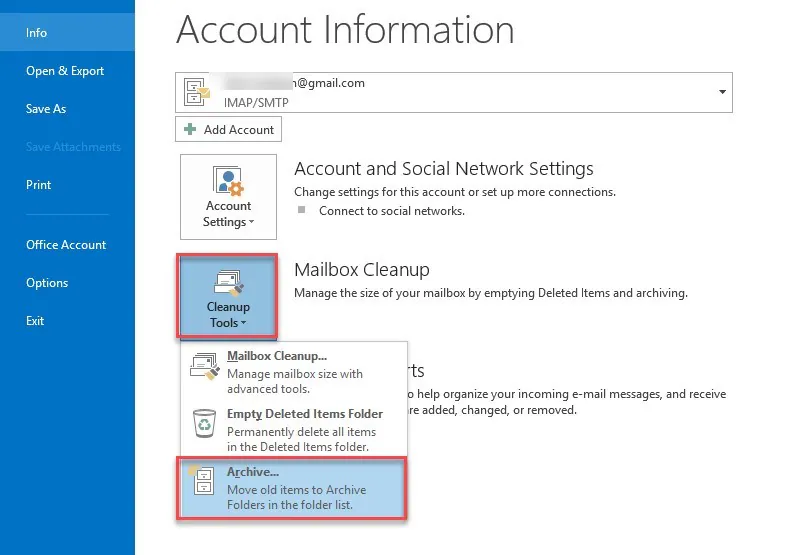

A crisp, clear display helps operators monitor details precisely. High-resolution screens are especially beneficial for complex visuals and data-heavy applications. - Remote Access Capabilities

Web-based HMIs with remote monitoring capabilities allow operators to stay connected and respond to issues quickly, even from afar. - Data Logging and Visualization

Data tracking and graphical representation of trends are essential for analyzing historical performance and making data-driven decisions. - Multi-Language Support

For global operations, multi-language support ensures that the HMI system can accommodate a diverse workforce. - Robustness and Reliability

Industrial-grade HMIs need to withstand harsh conditions, such as extreme temperatures, moisture, dust, and high vibration.

Benefits of Implementing HMIs Screens and Displays

- Increased Operational Efficiency

HMIs streamline processes, reducing the need for manual checks and minimizing response time. This improvement in efficiency is a primary benefit across industries. - Enhanced Safety

Real-time monitoring allows operators to detect abnormalities and react immediately, helping to avoid accidents and maintain workplace safety. - Cost Savings

By improving process control and reducing downtime, HMI technology can lead to significant cost savings in maintenance and operation. - Improved Data Analysis

HMIs that include data logging enable better analysis of trends, helping organizations to optimize performance and prevent recurring issues.

Choosing the Right HMI Screen and Display

Identify the Environment

Consider where the HMI will be used. Harsh environments, like manufacturing floors, require rugged screens that can handle dust, moisture, and impact.

Determine the Necessary Features

Align the HMI features with your operational needs. For example, if remote access is essential, opt for a web-enabled HMI.

Consider Scalability

Choose an HMI solution that can grow with your business. Scalable systems are easier to upgrade and integrate with new technology as your needs evolve.

Assess Compatibility

Make sure the HMI is compatible with existing equipment and networks. Compatibility reduces installation time and potential integration issues.

Evaluate Cost vs. Value

It’s important to balance cost with value. A more advanced, slightly higher-cost HMI could pay off in the long run by reducing downtime and increasing productivity.

Common Applications of HMIs Screens and Displays

Manufacturing and Automation

HMIs are widely used to monitor and control production lines. They help operators oversee machine operation, track output levels, and manage energy consumption.

Power and Utilities

In the energy sector, HMIs control and monitor systems like wind turbines, solar panels, and electrical grids, ensuring efficiency and reliability.

Healthcare and Laboratory Equipment

HMIs streamline data handling, process monitoring, and equipment control in medical devices and lab settings, improving accuracy and workflow efficiency.

Transportation and Logistics

From railway control systems to warehouse logistics, HMIs are used to monitor vehicle status, coordinate schedules, and oversee freight handling.

FAQs on HMIs Screens and Displays

How do HMIs improve efficiency?

By enabling real-time monitoring and quick control, HMIs allow operators to make faster, better-informed decisions, which enhances productivity.

Are HMIs expensive to implement?

Costs vary based on complexity and features. Basic HMIs can be affordable, while advanced systems may involve higher investment but offer better ROI.

What is the best type of HMI for remote access?

Web-based and mobile HMIs are ideal for remote access, allowing monitoring from various devices without physical presence.

Can HMIs withstand harsh environments?

Yes, industrial-grade HMIs are designed for durability, with features that withstand dust, moisture, and extreme temperatures.

How do HMIs enhance safety?

Real-time data visualization helps operators spot anomalies quickly, allowing for immediate responses that prevent accidents and maintain safety.

Conclusion

Selecting the right HMIs screens and displays is essential to optimize industrial operations, enhance efficiency, and improve safety. By understanding your operational requirements and the features of each HMI type, you can choose a system that meets your goals and fits your environment. From manufacturing floors to healthcare facilities, HMI technology is indispensable for monitoring, control, and data-driven decision-making.