Selecting the appropriate cutting machine for hard and brittle materials is crucial to ensure precision, efficiency, and safety in various industrial applications. Materials such as stone, ceramics, glass, and certain metals require specialized equipment capable of handling their unique properties without causing damage or excessive wear. This article delves into the key considerations when choosing a cutting machine for such materials, with a focus on diamond wire saw cutting machines and the offerings from Ensolltools.

Understanding Hard and Brittle Materials

Hard and brittle materials are characterized by their high hardness and low toughness. They can withstand significant compressive forces but are prone to cracking or shattering under tensile stress. Common examples include:

- Natural Stones: Granite, marble, and quartz.

- Ceramics: Tiles, porcelain, and advanced technical ceramics.

- Glass: Optical glass, tempered glass, and specialty glasses.

- Metals: Tungsten, cast iron, and certain high-carbon steels.

The inherent brittleness of these materials necessitates cutting methods that minimize mechanical stress and prevent fractures.

Key Factors in Selecting a Cutting Machine

- Cutting Precision and Accuracy

- Tolerance Levels: Ensure the machine can achieve the required dimensional tolerances for your application.

- Surface Finish: The machine should provide a smooth surface finish to reduce the need for secondary processing.

- Material Compatibility

- Versatility: Opt for machines capable of handling various materials if your operations involve multiple substrates.

- Specificity: For specialized applications, choose a machine designed explicitly for the material in question.

- Cutting Speed and Efficiency

- Production Volume: High-speed machines are essential for large-scale production to meet output demands.

- Cycle Time: Evaluate the machine’s cutting speed to ensure it aligns with your operational timelines.

- Machine Durability and Maintenance

- Build Quality: Robust construction materials and components extend the machine’s lifespan.

- Maintenance Requirements: Consider machines with user-friendly maintenance procedures to minimize downtime.

- Safety Features

- Protective Enclosures: Shields and guards to protect operators from debris and moving parts.

- Emergency Stop Functions: Easily accessible controls to halt operations instantly in case of emergencies.

Diamond Wire Saw Cutting Machines

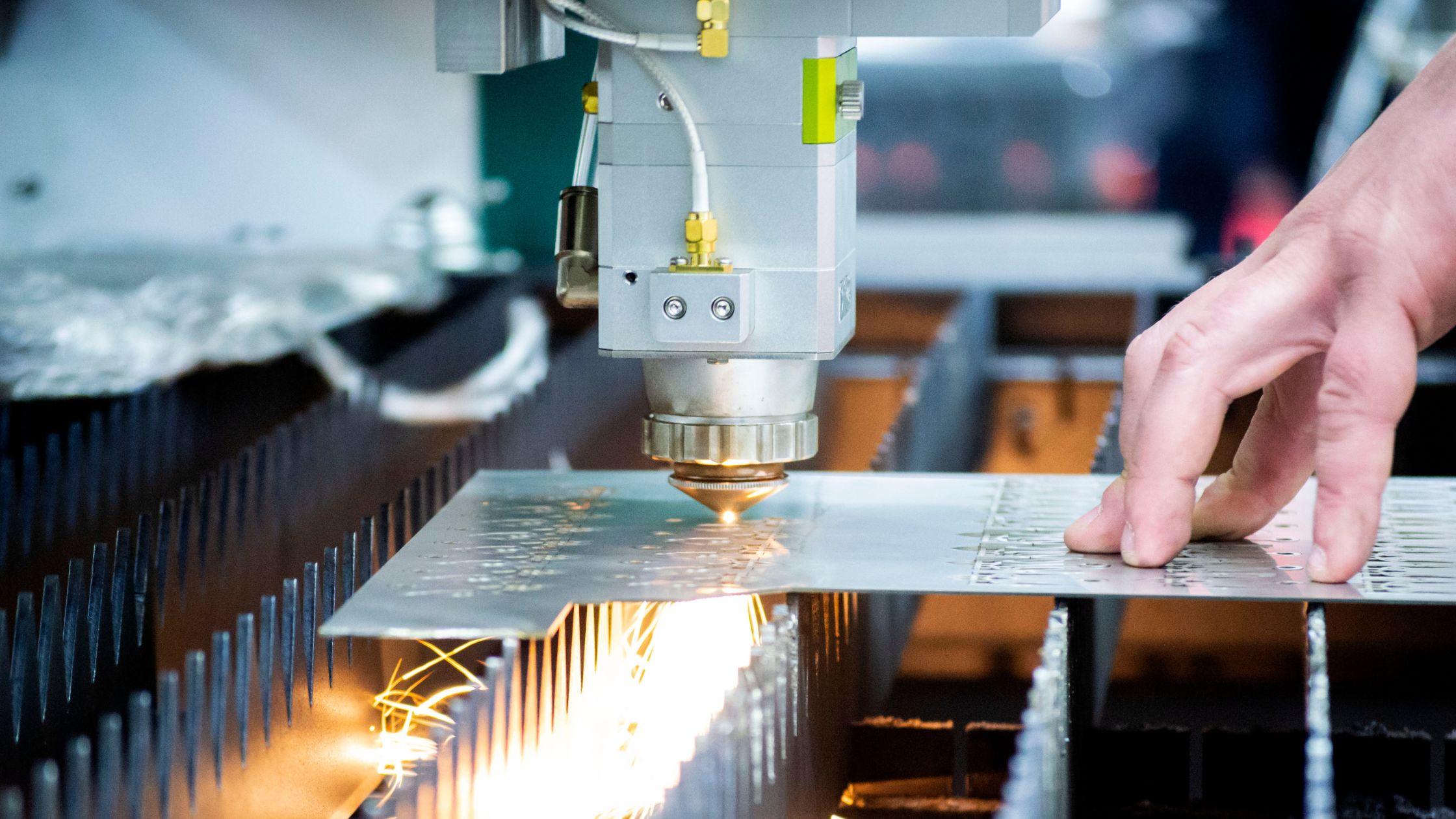

Among the various cutting technologies, diamond wire saw cutting machine have emerged as a superior choice for hard and brittle materials. These machines utilize a continuous loop of wire embedded with diamond abrasives to perform precise cuts. The advantages include:

- Minimal Mechanical Stress: The cutting action reduces the risk of inducing cracks or fractures.

- High Precision: Capable of achieving tight tolerances and intricate shapes.

- Versatility: Suitable for a wide range of materials, including those with complex geometries.

- Reduced Material Waste: Thin cutting kerf minimizes material loss during the cutting process.

Ensolltools: Pioneering Diamond Wire Saw Technology

Ensolltools stands out as a leading manufacturer specializing in diamond wire saw cutting machine. Their commitment to innovation and quality is evident in their diverse product lineup, tailored to meet various industrial needs.

Highlighted Models from Ensolltools

- ESG200-2T

- Design: Gantry-style cutting machine with vertical motion.

- Cutting Capacity: Accommodates materials up to 200mm in length, width, and height.

- Features:

- Compact structure with dimensions of 800×680×1610mm.

- Waterproof body suitable for wet cutting applications.

- Adaptive tensioning system eliminating the need for manual adjustments.

- Noise-free operation ensuring a stable and precise cutting environment.

- ESG200-2T-S

- Design: Multi-angle cutting capabilities with an added rotation function.

- Cutting Capacity: Handles materials up to 200mm in all dimensions.

- Features:

- Tilting worktable enabling cuts at various angles.

- Worktable rotation of 360° horizontally and a downward tilt from 0° to 15°.

- Automatic tension adjustment for ease of use.

- Quick and easy diamond wire replacement within one minute.

- ESG400-4T

- Design: Enlarged gantry cutting machine suitable for larger materials.

- Cutting Capacity: Supports materials up to 400mm in length, width, and height.

- Features:

- Expanded size for accommodating bigger workpieces.

- Equipment dimensions of 1003×882×1756mm.

- Maintains high precision with a positioning accuracy of ±0.05mm.

- Adjustable cutting thickness ranging from 0.1mm to 400mm.

Conclusion

Selecting the right cutting machine for hard and brittle materials is a critical decision that impacts the quality, efficiency, and safety of your operations. Diamond wire saw cutting machines, particularly those offered by Ensolltools, provide a compelling solution with their precision, versatility, and advanced features. By carefully evaluating your specific material requirements and operational needs, you can choose a machine that enhances productivity while ensuring superior cutting performance.

FAQs

- What makes diamond wire saw cutting machines suitable for brittle materials?

Diamond wire saws apply minimal mechanical stress during cutting, reducing the risk of cracks and fractures in brittle materials. - Can Ensolltools’ machines handle materials other than stone and ceramics?

Yes, Ensolltools’ diamond wire saw machines are versatile and can cut various materials, including metals and glass. - How does the adaptive tensioning system benefit the cutting process?

The adaptive tensioning system automatically adjusts the wire tension, ensuring consistent cutting performance without manual intervention. - Are these machines suitable for both industrial and laboratory settings?

Absolutely. Ensolltools offers models like the ESV-3S, which is compact and ideal for laboratory use, as well as larger models for industrial applications. - What support does Ensolltools provide post-purchase?

Ensolltools offers comprehensive after-sales support, including maintenance services, technical assistance, and readily available replacement parts.